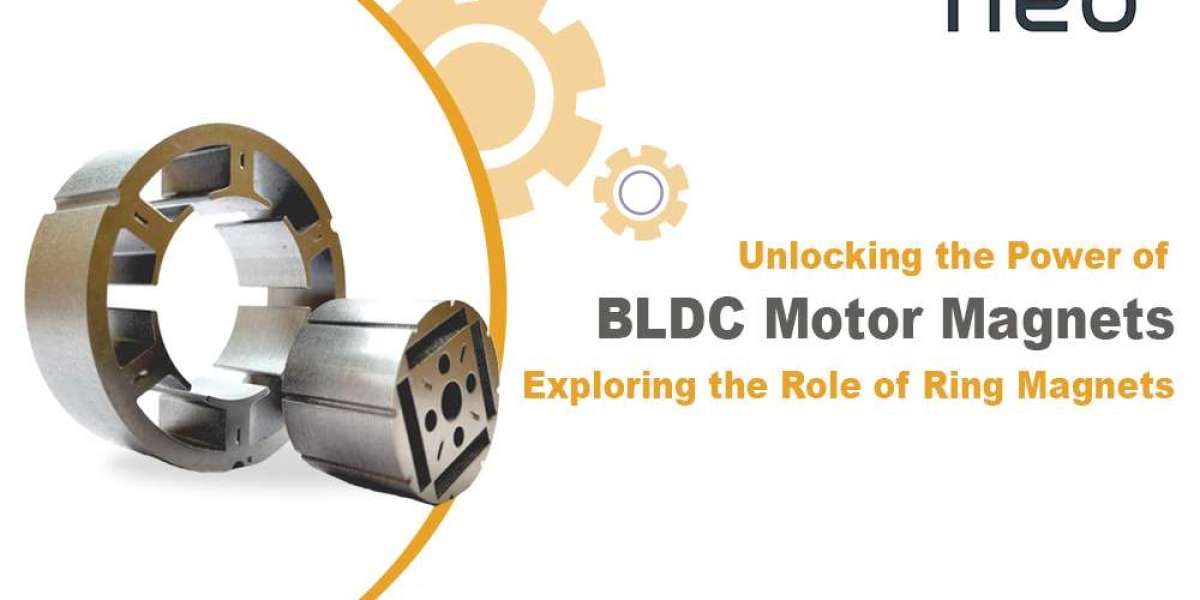

In the realm of electric motors, Brushless DC (BLDC) motors stand out for their efficiency, reliability, and versatility. At the core of these motors lie a crucial component: magnets. Among the various types of magnets employed, ring magnets play a pivotal role, contributing to the performance and efficiency of BLDC motors.

Understanding BLDC Motors and Magnets

Brushless DC motors have gained widespread adoption across various industries due to their ability to provide high torque, precise speed control, and low maintenance requirements. Unlike their brushed counterparts, BLDC motors rely on electronic commutation to drive the motor's rotation, eliminating the need for brushes and commutators.

Magnets are integral to the operation of BLDC motors, serving as the source of the motor's magnetic field. The interaction between the magnetic field generated by the permanent magnets and the electromagnetic field produced by the motor's windings is what drives the motor's rotation.

The Role of Ring Magnets

Among the different magnet configurations used in BLDC motor magnets, offer unique advantages. Ring magnets, also known as donut magnets or tube magnets, are cylindrical magnets with a hole in the center. This design allows for a more efficient use of magnetic material compared to other shapes, resulting in improved performance and energy efficiency.

These are often employed in the rotor assembly of BLDC motors, where they are positioned around the motor's shaft. This configuration enhances the magnetic flux density, leading to higher torque output and smoother operation. Additionally, the symmetrical distribution of magnetic flux around the rotor helps minimize cogging torque, resulting in quieter operation and reduced vibration.

Advantages of Magnets in BLDC Motors

- Higher Torque Density: The compact design of these magnets allows for a higher concentration of magnetic flux within the motor, enabling greater torque output without increasing the motor's size or weight.

- Improved Efficiency: The efficient use of magnetic material in these magnets reduces energy losses and enhances the overall efficiency of BLDC motors, making them ideal for applications where energy conservation is crucial.

- Enhanced Thermal Performance: These magnets facilitate better heat dissipation within the motor, preventing overheating and extending the motor's lifespan. This is particularly advantageous in high-performance applications where thermal management is critical.

Suggesting MQI Technology

In the quest for further enhancing the performance and efficiency of BLDC motors, the adoption of advanced technologies such as MQI (Magnetic Quadrupole Interaction) technology holds great promise. MQI technology leverages sophisticated magnet designs and advanced magnetic materials to optimize the performance of BLDC motors.

By harnessing the principles of magnetic quadrupole interaction, MQI technology enables precise control over the magnetic field within the motor, resulting in improved torque output, reduced power consumption, and enhanced overall efficiency. Furthermore, MQI technology offers opportunities for miniaturization and cost reduction, making it an attractive option for a wide range of applications.

In conclusion, these magnets play a crucial role in maximizing the performance and efficiency of BLDC motors. Their unique design and inherent advantages make them indispensable components in modern electric propulsion systems. As the demand for energy-efficient and high-performance motors continues to rise, innovations such as MQI technology are poised to drive the future evolution of BLDC motor magnet technology.