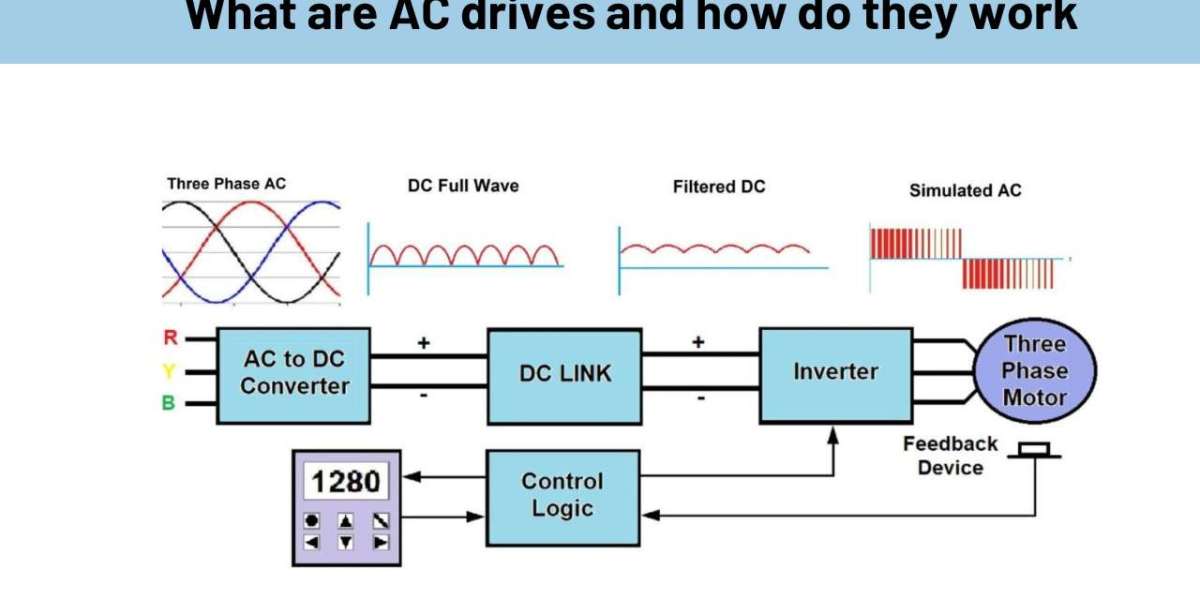

Alternating current (AC) drives, also known as adjustable frequency drives or variable frequency drives (VFDs), are technological devices used to control the torque and speed of electric motors. The fixed frequency and voltage of the power supply are converted into a variable frequency and voltage to match the desired motor speed.

1.Power Supply:

The AC drive is connected to an AC power source, which is typically a three-phase power source.

Allen Bradley AC drive frequently draws its power from sources of alternating current (AC). The most common design for industrial applications is a three-phase power supply. The voltage and frequency of the power supply are set by the specific requirements of the AC drive.

The power supply provides the electrical energy needed to run the AC drive. It serves as the input source for the internal parts of the AC drive, allowing it to transform and control the power supplied to the motor. The power supply and the AC drive must be the proper size and compatible for a dependable and efficient operation.

2.Rectifier:

The incoming AC power is first converted into DC power by a rectifier. A diode bridge is frequently used as the rectifier, which transforms the AC waveform into a pulsing DC waveform.

Transforming the AC waveform into a pulse-like DC waveform is the rectifier's main job. As the polarity of the AC voltage alternates, the diodes in the rectifier block current flow in one direction and allow it in the other, creating a rectified waveform that flows in a single direction.

The rectified DC waveform is then delivered to the DC link, which functions as a storage or buffer component in the AC drive system. The DC link's capacitors smooth out the pulsing waveform, making it more uniform.

3.DC Link:

The pulsing DC power from the rectifier is then smoothed out and stored in a DC link, typically with the aid of capacitors. The DC link, which acts as a buffer, offers a constant DC voltage supply.

Check :- Allen Bradley PowerFlex 4M AC drives

4.Inverter:

The DC link provides DC power to the inverter component of the AC drive. IGBTs, which are frequently used as power electronic switches in inverters, quickly turn on and off DC power.

The inverter portion of the AC drive is made up of power electronic switches, which are frequently insulated gate bipolar transistors (IGBTs) or metal-oxide-semiconductor field-effect transistors (MOSFETs). These switches are operated by the drive's electronics, which quickly turn on and off the DC power.

The inverter uses pulse width modulation (PWM) methods to create the AC waveform. With PWM, power switches are quickly turned on and off at a high frequency, typically in the kilohertz range. By adjusting the width or duration of each switching pulse, the inverter controls the actual voltage level delivered to the motor.

5.Pulse Width Modulation (PWM):

The inverter uses pulse width modulation (PWM) techniques to produce an AC waveform with adjustable frequency and voltage. PWM works by rapidly turning power switches on and off at a high frequency to create a series of voltage pulses. The length or width of each pulse determines the actual voltage level that is delivered to the motor.

6.Motor Output:

The AC waveform generated by the inverter is then fed to the electric motor. To alter the output power's speed and torque, the AC drive modifies the output power's frequency and voltage.

7.Control Signals

The AC drive receives control signals from an external device, such as a control panel or programmable logic controller (PLC). These signals indicate the intended motor speed and other operational parameters.

- Control Panel: On many AC drives, there is a control panel with buttons, knobs, and displays. Using the control panel, operators can manually enter commands and set parameters on the drive. They can alter the desired motor speed, alter other operating settings, and start or stop the motor.

- External Control Signals: AC drives can receive control signals from PLCs or other control systems, among other sources. These control signals could be analog (such as voltage or current signals) or digital (such as binary signals or serial communication protocols). The external control signals contain all of the necessary motor speed, direction, acceleration/deceleration rates, and other parameters.

8.Feedback:

AC drives frequently have feedback components like encoders or sensors that provide data on the actual motor speed and other parameters. Based on this feedback, the drive modifies its output in order to maintain the desired motor performance.

9.Closed-Loop Control:

Using control inputs and feedback, the AC drive continuously modifies the frequency and voltage of the output power to the motor. This closed-loop control system allows the motor to operate at the desired speed and torque.

- Feedback Devices: Closed-loop control is dependent on feedback elements, such as encoders or sensors, that provide real-time information about the motor's speed, position, or other relevant variables. These devices report information to the AC drive while monitoring motor performance.

- Comparison: The feedback signals are compared to the necessary reference signals, such as the predetermined motor speed or torque. The AC drive compares the actual feedback values with the desired values to find any deviations or errors.

- Error Calculation: When the desired reference signal and the actual feedback signal differ from each other, an error signal is generated. This error signal represents the difference between the expected and actual motor performance.

Asteam Techno Solutions Pvt. Ltd. was established in 2017 with a perspective to become a single-source supplier in Automation industry and is now regarded as one of the top Industrial Automation Parts Suppliers in India. Asteam Techno Solutions Pvt. Ltd. offer you the best products such as HMI, PLC, Power Supply, Servo Motor etc. that we sourced from the trusted brands like Allen Bradley, Siemens, Phoenix Contact, Moxa, Vipa and many more, which give you the maximum possible outcomes.